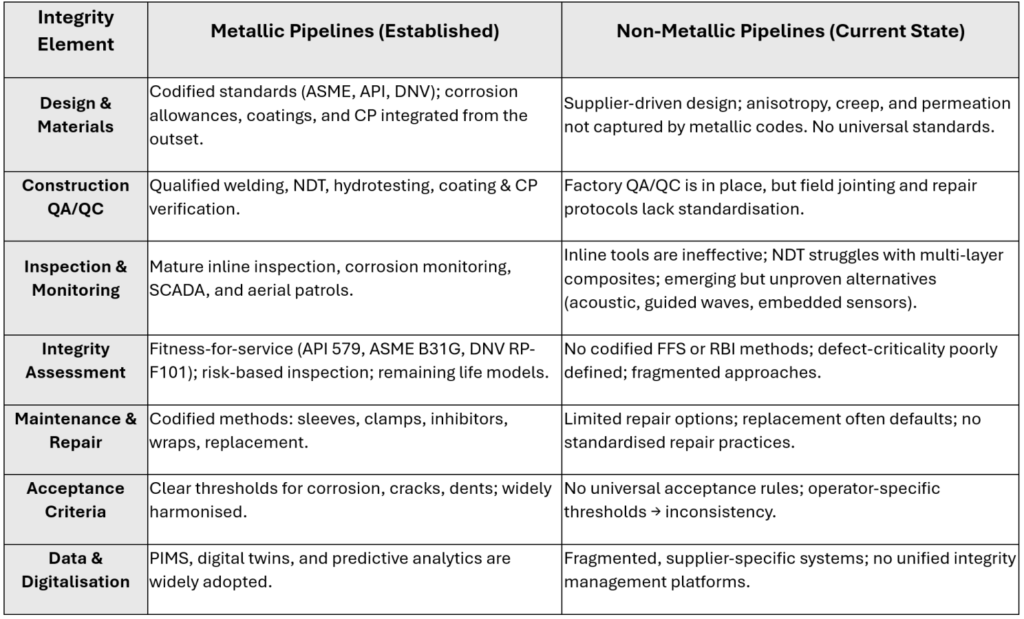

1. The Established World of Metallic Pipeline Integrity

Integrity management for metallic pipelines is a mature and codified discipline, built on more than a century of operational experience. It forms a closed-loop system that is consistent, repeatable, and trusted worldwide.

The main elements include:

- Design and Materials: Governed by well-defined codes (ASME, API, DNV), with corrosion allowances, coatings, and cathodic protection embedded from the outset.

- Construction QA/QC: Qualified welding, NDT, and hydrostatic testing to validate pressure containment and coating performance before commissioning.

- Inspection and Monitoring: Inline inspection tools, corrosion monitoring, CP surveys, SCADA, and aerial surveillance provide high visibility of pipeline condition.

- Integrity Assessment: Codified fitness-for-service methods (API 579, ASME B31G, DNV RP-F101) and risk-based inspection approaches to evaluate defects and predict remaining life.

- Maintenance and Mitigation: A wide toolbox of standardised interventions: inhibitors, sleeves, clamps, composite wraps, replacement, and CP optimisation.

- Data and Digitalisation: Integrated Pipeline Integrity Management Systems (PIMS), digital twins, and predictive analytics to connect inspection, monitoring, and planning.

Together, these elements create a robust, globally standardised integrity framework that provides operators and regulators with high confidence in the safe, reliable operation of metallic pipelines across their lifecycle.

2. The Emerging Challenge of Non-Metallic Pipelines

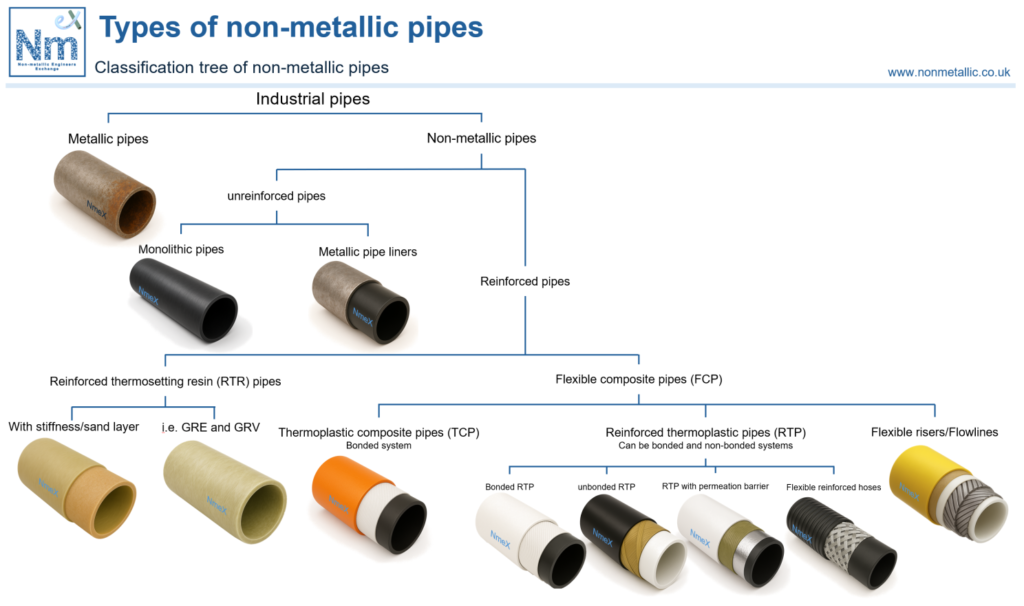

Non-metallic pipelines, including reinforced thermoset resin (RTR), reinforced thermoplastic pipe (RTP), and thermoplastic composite pipe (TCP), are increasingly deployed to overcome the corrosion challenges of steel. However, when it comes to asset integrity, the frameworks that underpin metallic pipelines are not directly transferable.

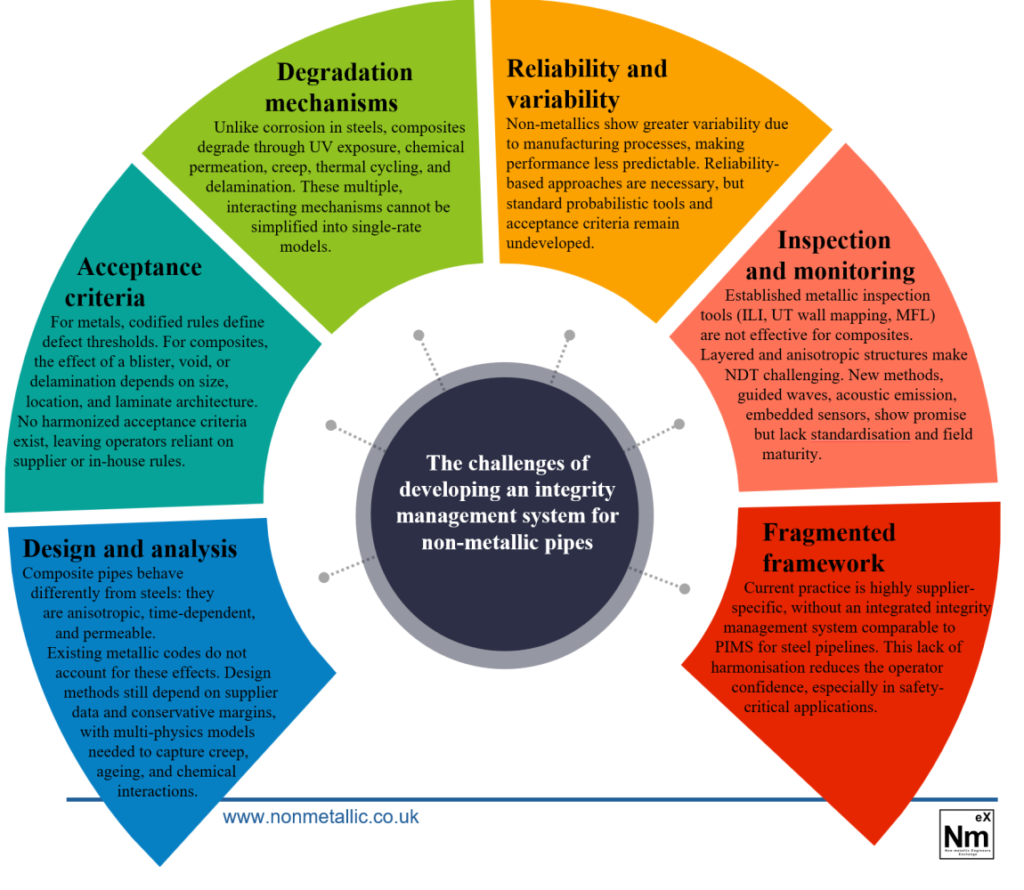

The challenges holding back asset integrity development for non-metallic pipes

Several critical gaps remain:

- Design and Analysis Unlike steels, composites are anisotropic, time-dependent, and permeable to gases and fluids. Metallic design codes do not capture these behaviours. Instead, non-metallics require multi-physics models that address creep, ageing, and chemical interactions. Today, design still relies heavily on supplier data and conservative safety margins.

- Reliability and Variability Manufacturing processes introduce more variability in material properties compared to steel. This makes reliability-based design essential, yet industry-wide probabilistic tools and acceptance criteria are not yet established.

- Degradation Mechanisms Corrosion is not the dominant threat. Instead, ageing arises from UV exposure, permeation, thermal cycling, creep, and fatigue-driven delamination. These mechanisms are complex and multi-factorial, and cannot be simplified into corrosion-rate style models.

- Inspection and Monitoring The tools that revolutionised metallic integrity, ILI pigs, ultrasonic wall mapping, MFL, are ineffective in composites. Conventional NDT also struggles with layered, anisotropic structures. Emerging solutions such as acoustic emission, guided waves, advanced ultrasonics, and embedded sensors are promising but not yet field-proven or standardised.

- Acceptance Criteria Codified thresholds exist for metallic defects (e.g., ASME B31G for corrosion pits). In composites, the impact of a void, blister, or delamination depends heavily on size, location, and laminate architecture. No universally accepted acceptance criteria exist, leaving operators to rely on in-house rules.

- Fragmented Framework The result is a patchwork of supplier-specific practices, with no harmonised integrity management system equivalent to PIMS. This limits confidence, especially in critical and regulated applications.

Therefore, although non-metallic pipelines deliver clear material advantages, corrosion resistance, lighter weight, and faster installation, but their integrity management remains underdeveloped. The absence of codified design rules, defect acceptance criteria, proven inspection tools, and integrated frameworks means the industry does not yet have the same level of assurance as with metallic systems.

Bridging this gap is essential if non-metallic pipelines are to move from niche applications to widespread adoption.

3. Rigid vs. Flexible Non-Metallic Pipelines

When discussing integrity management of non-metallic pipelines, it is important to distinguish between rigid composite pipes (RTRs such as GRE, GRV, etc.) and flexible pipes (such as FCPs and RTPs). Both are classed as non-metallics, but their structures and degradation behaviours are fundamentally different, with direct implications for integrity management.

3.1. Rigid Composite Pipes

Rigid pipes have a relatively simple architecture: fibre reinforcement (generally glass) embedded in a resin matrix, sometimes combined with a liner or outer coating. This structure is comparable to composite laminates long studied in aerospace, where extensive research exists on damage initiation and propagation. Across suppliers, rigid designs are broadly similar, meaning that integrity management principles can be more easily standardised.

The main challenge lies in inspection. Unlike aerospace laminates, rigid pipelines often have thick walls, which makes subsurface defect detection, such as voids, delaminations, or permeation-driven blistering, extremely difficult. While modelling approaches are transferrable, field-ready NDT solutions are not yet available at the required reliability.

3.2. Flexible Pipes

Flexible pipes are structurally far more complex and diverse. Designs vary significantly across suppliers and applications, incorporating:

- Bonded and unbonded layer configurations.

- A mix of polymeric, composite, and metallic reinforcements (tapes, wires, laminates).

- Multiple material interfaces with different ageing and degradation mechanisms.

This diversity makes generic integrity approaches very difficult to establish. A defect that is critical in one flexible pipe design may be benign in another. Furthermore, the multi-layer, multi-material structure creates major challenges for inspection and monitoring, as conventional NDT struggles to penetrate and discriminate between layers.

In principle, integrity management of rigid composites is more achievable: their structures are simpler, better studied, and more consistent across suppliers. For flexibles, however, the wide variety of architectures and material combinations means integrity frameworks are likely to remain fragmented and supplier-specific for the foreseeable future.

The variety of flexible pipes in comparison to rigid pipes.

4. Early Attempts at Integrity Management

Although a comprehensive integrity management framework for non-metallics has not yet been established, several supplier- and technology-driven initiatives illustrate early efforts to build elements of such a system, particularly for flexible pipelines. These examples are fragmented and not standardised, but they point towards the building blocks of future frameworks.

4.1. Flexpipe Pulse: Digital Installation Traceability

Mattr‘s Flexpipe Pulse provides a cloud-based digital platform to improve installation quality and accountability. Using mobile applications, GPS-enabled tracking, and cloud data storage, it generates traceable, verifiable records of fittings, joints, and installation activities. While focused on the construction phase rather than in-service inspection, it demonstrates how digital traceability can reduce risk and provide operators with reliable historical records for each asset. Read more here: https://www.flexpipesystems.com/storage/2025/02/Pulse-One-Pager-02.25.pdf?v=1.021225

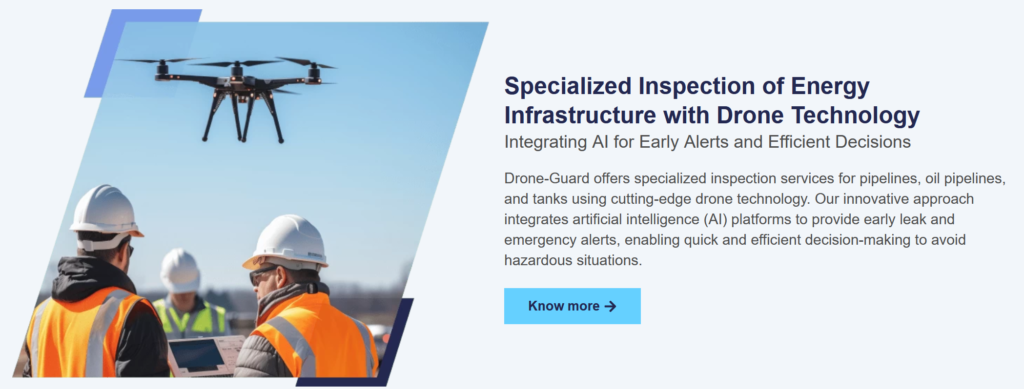

4.2. Imantt Drone-Guard: Remote Aerial Surveillance

Imantt’s Drone-Guard service uses drones with AI-based analytics to conduct above-ground inspections of pipelines and tanks. High-resolution imaging, combined with automated pattern recognition, enables early identification of leaks or anomalies and provides real-time alerts to operators. This mirrors well-established aerial surveillance practices in metallic pipelines, but adapted to non-metallic applications, where inline inspection remains impractical. Read more here: https://www.imantt.com/drone-guard/#form

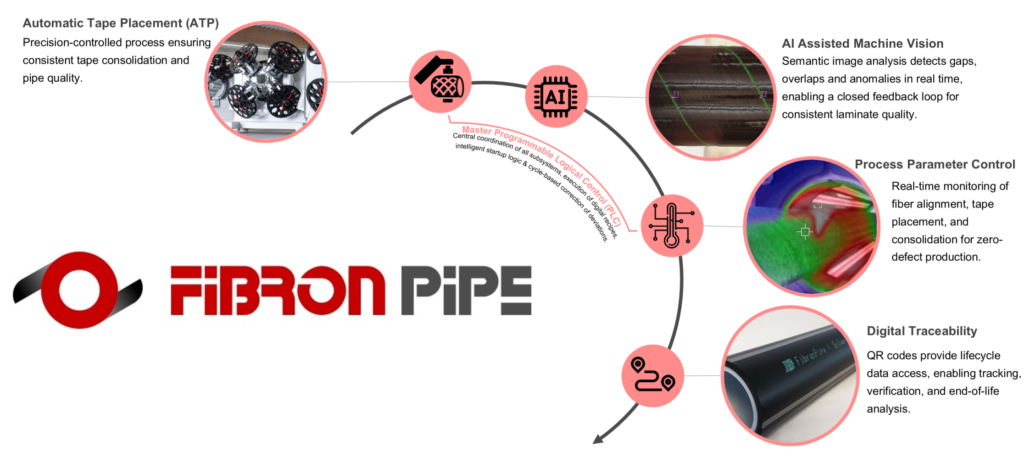

4.3. Fibron Pipe GesmbH: QR-Enabled Manufacturing Traceability

FibronPipe emphasises the importance of manufacturing quality; Their product has advanced integrity at the manufacturing stage through automated production and inline quality control of TCPs. Every meter of pipe can be tagged with a QR code, linked to its full digital manufacturing record, including process parameters, batch data, and QA/QC results. This enables unprecedented traceability down to the meter level, which, combined with the installation platform, it could form a foundation for lifecycle integrity by directly connecting field performance with manufacturing quality data. Read more here: https://www.fibronpipe.com/technology

These initiatives illustrate that the industry is already experimenting with the tools of integrity: digital traceability, remote inspection, and manufacturing quality control. However, they remain supplier-specific solutions rather than industry-wide standards. For these approaches to translate into true integrity management, they must be integrated with codified acceptance criteria, reliable NDT, and unified digital frameworks that span the full pipeline lifecycle.

5. The Missing Links

The contrast between metallic and non-metallic pipeline integrity becomes clear when viewed side by side. Metallic systems benefit from a century of codification, while non-metallics are still in a fragmented state, with critical elements absent.

6. Towards a Non-Metallic Integrity Framework

Closing these gaps requires more than incremental adaptation of metallic practices. Non-metallics are fundamentally different materials and demand a purpose-built integrity management framework. Several pillars are critical:

- Composite-Specific Threat Assessment Establishing standard threat libraries that capture non-metallic ageing modes, permeation, blistering, UV degradation, creep, fatigue-driven delamination, rather than corrosion-based frameworks.

- Multi-Scale Simulation and Reliability Tools Developing analysis methods that couple material variability with multi-physics behaviour (structural, thermal, chemical). These must evolve towards probabilistic, reliability-based design, not just deterministic margins. Examples of such frameworks include this study: https://doi.org/10.1016/j.compositesb.2019.106925

- Defect Propagation Models and Acceptance Criteria Creating models that link micro-scale defects (voids, delaminations) with macro performance (burst, fatigue) to define codified defect thresholds, the single biggest missing link today.

- Tailored Inspection and Monitoring Investing in inspection methods fit for composites: advanced ultrasonics, acoustic emission, guided waves, fibre-optic sensing, and digital health monitoring integrated into SCADA.

- Standardisation and Integration Bringing these elements together into a harmonised framework equivalent to PIMS for metallics, a closed loop from design → monitoring → assessment → repair, supported by shared standards, industry guidelines, and regulatory alignment.

The task ahead is significant, but the trajectory is clear. Industry initiatives are already laying foundations, from digital installation traceability to QR-based manufacturing records and drone inspection platforms. The next step is integration and codification, turning fragmented practices into a unified framework.

By doing so, non-metallic pipelines can move from promising alternatives to fully trusted infrastructure, with an integrity system as robust as that enjoyed by steel.

7. NmeX Contribution: A Roadmap for Progress

At this stage, there is no unified integrity management framework for non-metallic pipelines. What exists is fragmented, supplier-led initiatives, isolated research studies, and early attempts at digital tools. The question is not whether such a framework is needed, but how the industry will get there.

This is where the Non-Metallic Engineers Exchange (NmeX) sees its role as a neutral hub for knowledge and awareness. The vision for NmeX is to evolve into a place where the community can:

- See what is happening today, a clear, up-to-date picture of ongoing research, new inspection methods, trial standards, and field experiences.

- Understand what is transferable from metallic systems, and where non-metallics demand different solutions.

- Follow emerging developments such as digital traceability, defect databases, and multi-scale modelling, without having to search across fragmented sources.

- Connect ideas and perspectives from operators, suppliers, researchers, and regulators in one open space.

The aim is simple: to make progress visible, connected, and accessible. Today, an operator or engineer interested in non-metallic integrity must navigate scattered technical papers, supplier brochures, or in-house knowledge. Tomorrow, with NmeX, they should be able to find a curated overview, a roadmap showing what is ready now, what is being developed, and what remains missing.

Over time, this roadmap can expand: from summarising knowledge, to showcasing good practice, to eventually helping align the building blocks of a true integrity framework for non-metallic pipelines.