Introduction

The global oil and gas industry continues to evolve, with increasing focus on reducing lifecycle costs, improving corrosion management, and enabling faster, more flexible field development. In this context, non-metallic materials such as RTR (Reinforced Thermoset Resin) and FCP (Flexible Composite Pipe) are emerging as powerful enablers of change.

Traditionally, steel and corrosion-resistant alloys have dominated oilfield pipeline systems. While these materials offer strength and reliability, they also bring inherent challenges: susceptibility to corrosion, high maintenance costs, long lead times, and complex installation requirements.

Non-metallic materials offer an alternative, one that is already proven in many applications. Yet adoption remains inconsistent. Many engineers still view non-metallics as limited to utilities or water lines, unaware that composite pipes have been successfully deployed in high-pressure flowlines, gas injection systems, and even in some downhole trials.

At the same time, developers and suppliers of non-metallic solutions often lack visibility into real-world field conditions: What pressure ranges should they design for? What are the dominant pipe sizes? What chemical exposures matter most? What is the scale of the opportunity?

This article aims to answer those questions. It provides a structured, field-oriented overview of the key pipeline systems in onshore oil and gas operations, along with the associated service conditions and technical requirements. It also highlights the specific roles non-metallic materials can play in replacing or supplementing metallic systems, offering insight for both engineers evaluating options, and manufacturers looking to align their products with operational needs.

Market and Technical Gap

Despite the growing presence of non-metallic materials in oil and gas infrastructure, their adoption remains highly uneven across regions, operators, and system types. A significant barrier is the awareness gap between what non-metallics can do and what engineers and asset planners believe they are capable of.

For many engineers, the perception persists that non-metallic materials are only suitable for utility or low-pressure water lines. This overlooks decades of field data and successful deployments in flowlines, gas and water injection systems, produced water handling, and even early downhole applications. The consequence? Missed opportunities for lowering lifecycle costs and enhancing asset integrity.

On the supplier side, material developers often lack a clear view of the oilfield’s technical reality. Product offerings are sometimes mismatched to field requirements because developers don’t have reliable data on:

- Typical pipe lengths, diameters, and pressure ratings

- Expected temperature ranges across pipeline types

- Fluid types and their chemical compatibility requirements

- Regional operator preferences and qualification pathways

This disconnect limits innovation and slows the qualification of advanced materials that could otherwise replace or supplement steel systems.

The following sections aim to support closing this gap by presenting a consolidated overview of pipeline service conditions and material options, to help engineers make informed choices and suppliers align their product development with field demand.

Pipeline System Overview and Non-Metallic Potential

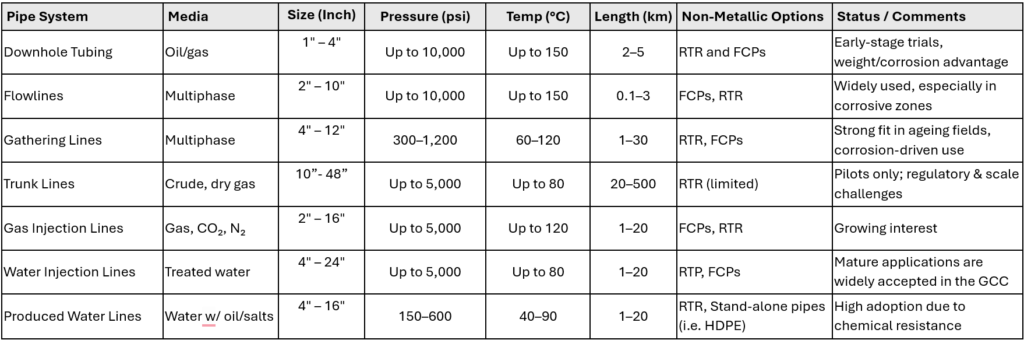

For a typical onshore oil and gas facility, the following pipe systems and their operational windows are expected:

For a dynamic overview of the entire onshore pipeline system, from injection lines to trunklines, watch the short video walkthrough. The video maps each pipeline type listed in the table to the corresponding service conditions and non-metallic options discussed in the table. It’s a quick way to visualise where materials like RTRs and FCPs can be applied across the field.

Field Example: Production and Flowline Systems

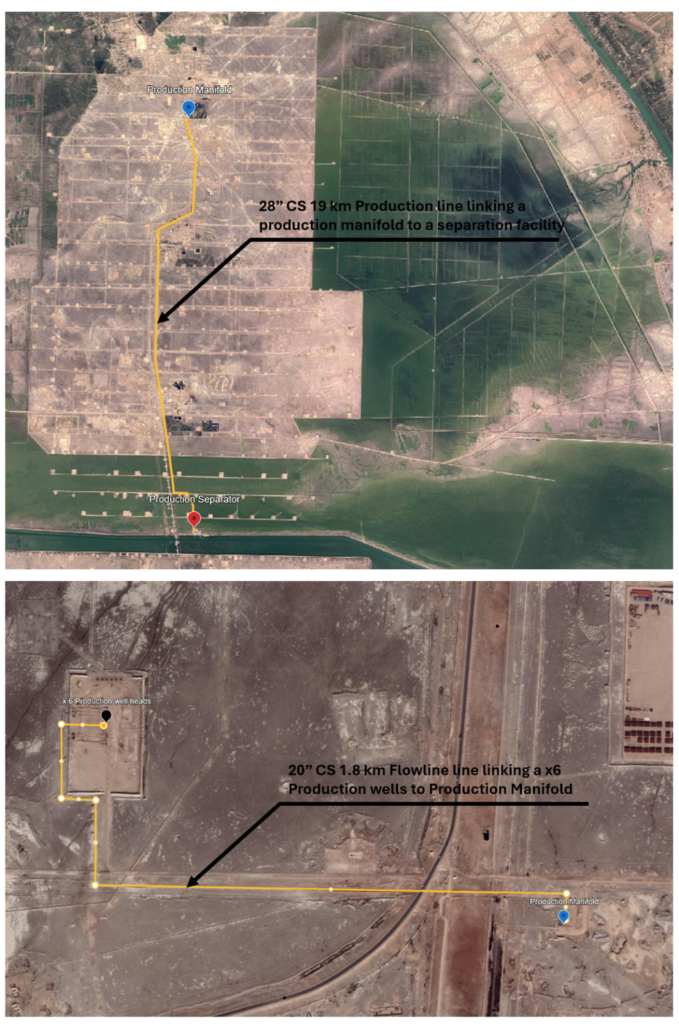

The satellite imagery above illustrates two real-world examples of onshore oilfield pipeline systems:

- A 28″ carbon steel production trunkline spanning 19 km, connecting a production manifold to a separation facility.

- A 20″ carbon steel flowline stretching 1.8 km, linking a cluster of production wells to a manifold.

These examples reflect common infrastructure layouts across the region, with distances, diameters, and functions that fall well within the operational envelope of advanced non-metallic pipeline technologies. In corrosion-sensitive environments or where rapid deployment is needed, RTRs and FCPs can serve as direct or partial replacements, offering lower maintenance and faster installation.

Such field cases help bridge the gap between abstract specifications and real deployment, reaffirming that non-metallics are not niche substitutes but viable mainstream solutions. And as the next figure shows, this opportunity is only growing.

Example from field operations showing a 28″ CS production line (19 km) and a 20″ CS flowline (1.8 km).

A Growing and Ageing Infrastructure, Opportunity in Both Directions

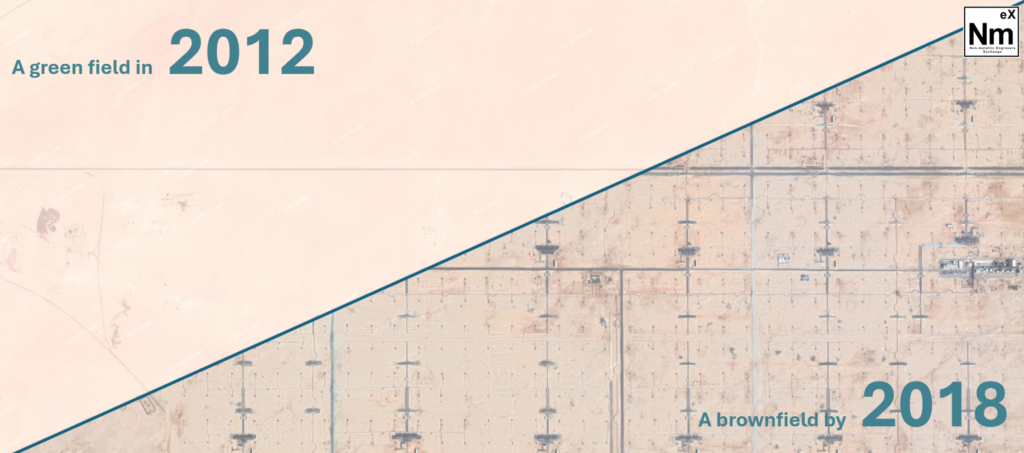

The time-lapse satellite imagery above shows a stark transformation: a once-barren oilfield landscape in 2012 has been densely developed by 2018 with extensive wellpads, trunklines, and production infrastructure. This rapid growth reflects the ongoing pace of onshore oil and gas development, especially across the Middle East.

For non-metallics, this trend reinforces a dual opportunity.

- First, greenfield developments represent a chance to specify non-metallic systems from the outset, enabling faster installation, reduced corrosion risk, and lower lifecycle costs.

- Second, the aging metallic infrastructure shown in earlier phases highlights a retrofit market; pipelines laid just a decade ago are already showing signs of degradation and are costly to maintain in corrosive environments. Non-metallics can serve as targeted replacements in such brownfield contexts, extending asset life while reducing downtime and OPEX.

Material Selection Guidance

Selecting the correct non-metallic material for pipeline systems is critical, and errors in material choice can lead to costly failures, environmental risks, and operational downtime. Mismatches between material capabilities and field conditions have historically resulted in:

- Premature pipe rupture due to overpressure or thermal cycling

- Delamination or blistering caused by chemical incompatibility

- Joint failures in thermoplastics under high mechanical load

- Permeation issues in gas injection lines and production lines lead to serious H&S problems.

Understanding the mechanical, chemical, and thermal environment is therefore essential to ensure both safety and performance. Material choice should be driven by operating envelope, fluid composition, mechanical loads, and connection type.

To support this, NmeX is actively developing a digital Pipe Selection Guide tool to assist engineers in choosing the most suitable non-metallic materials for various oil and gas pipeline applications based on service conditions, regulatory requirements, and lifecycle performance. Some details can be seen here.

Choosing the right non-metallic material is not a one-size-fits-all decision. Each pipeline application involves a unique set of conditions and operational constraints that influence material suitability. Below is a more detailed guide to help engineers align non-metallic pipe technologies with field requirements:

RTRs (Reinforced Thermoset Resin Pipes)

- Best for: Low to high pressure service, water injection systems, produced water lines, and non-critical oil lines.

- Strengths: High chemical and corrosion resistance, long service life, available in a wide range of diameters.

- Limitations: Brittle behaviour under impact; typically, not used in high-pressure or dynamic loading applications, joining relies heavily on the jointer’s skill.

RTPs (Reinforced Thermoplastic Pipes, usually unbonded systems)

- Best for: Injection systems and low- to mid-pressure lines where flexibility, rapid deployment, and corrosion resistance are key.

- Strengths: Spoolable, low-weight, fast installation, excellent resistance to internal and external corrosion.

- Limitations: Limited size range (typically up to 4–8″), limited temperature resistance, permeation challenges, not ideal for sharp bends or above-ground exposure.

TCPs (Thermoplastic composite pipes, bonded systems)

- Best for: High-pressure flowlines, gas injection systems, and environments with dynamic loads.

- Strengths: Better permeation resistance, high-pressure and temperature ratings.

- Limitations: Higher cost, larger bend radius, which presents deployment limitations and reduced spoolable lengths for onshore applications which require road transport. Similarly to RTPs, temperature resistance relies on the thermoplastic(s) used.

Un-reinforced Thermoplastics Pipes (such as HDPEs)

- Best for: Low-pressure produced water systems, utility piping, and temporary flow applications.

- Strengths: Inexpensive, chemically resistant, flexible, easy to join via fusion welding and other joining methods.

- Limitations: Limited pressure and temperature capacity, deformation under long-term load, UV sensitivity without shielding.

By matching material capability with system demands, pressure class, media, thermal cycling, and mechanical exposure, engineers can safely and efficiently integrate non-metallics into both greenfield and brownfield projects.

Challenges and Barriers to Implementation

While the technical and economic potential of non-metallic pipeline systems is clear, their adoption faces a set of persistent implementation challenges that must be addressed to realise broader industry uptake:

- Qualification and Certification: Many operators require extensive qualification programs for new materials, especially in critical service lines. This can slow adoption and deter investment from smaller suppliers. Moreover, different regions and operators may enforce differing standards and testing regimes, increasing time-to-market for new technologies.

- Lack of Codes and Standards: Industry codes and recommended practices often lag behind innovation in non-metallic materials. For example, while ISO and API have made progress, there remains a lack of comprehensive, universally accepted guidelines covering the full performance envelope of advanced composites in high-pressure or high-temperature applications.

- Installation and Handling Expertise: Non-metallic systems are not plug-and-play replacements. They may require specialised jointing methods and handling practices to avoid damage during storage, transport, or installation. Field crews not trained in composite handling may inadvertently compromise system integrity.

- Integrity and Performance Uncertainty in Harsh Conditions: Lack of reliable NDT methods and Long-term performance data for non-metallics in environments such as high-CO₂ gas injection or thermally cycling produced water lines is still evolving. This lack of shared operational history can hinder adoption in safety-critical systems, even when lab data shows promise.

- Perception and Risk Aversion: A strong preference for metallic systems persists within engineering, procurement, and construction teams. Even when non-metallics are proven technically viable, decision-makers may default to traditional materials due to perceived risks, contractual conservatism, or lack of internal specification pathways.

- Cost Misconceptions: While total installed cost and lifecycle cost can favour non-metallics, the higher up-front material cost may dissuade adoption without a clear cost-benefit analysis supported by field data.

These barriers are not insurmountable. Solutions include expanding pilot projects, enhancing qualification test programs, establishing joint operator-industry guidance, and improving training. Equally important is knowledge transfer, making real-world application data more available across the ecosystem.

Platforms like NmeX Non-metallic Engineers Exchange play a key role here, providing data consolidation, guidance tools, and a shared technical language that bridges the gap between innovation and implementation.

A Market Opportunity Hiding in Plain Sight

Despite the challenges outlined earlier, from qualification hurdles to knowledge gaps, the strategic case for non-metallics remains compelling. Their expanding use in onshore oil and gas systems is not aspirational; it is already happening, just unevenly and often under the radar.

This is what makes the opportunity both urgent and overlooked:

- Broad, because non-metallics can serve nearly every pipeline system, from flowlines and injection networks to gathering systems and even emerging downhole applications.

- Deep, because they directly address critical operational needs: corrosion resistance, accelerated installation, lower maintenance burdens, and alignment with environmental and decarbonization targets.

Yet widespread adoption requires more than technical viability; it requires early-stage integration into project planning, fit-for-purpose standards, and clear lifecycle cost modelling.

For engineers, this means shifting from reactive to proactive material selection. For suppliers, it means tailoring solutions to the most common service envelopes. For enablers like NmeX Non-metallic Engineers Exchange , it means making real-world deployment data, digital tools, and field case studies more accessible to all stakeholders.

With the right visibility and collaboration, what has been a niche solution can become a mainstream engineering choice, one that brings resilience, sustainability, and value to energy systems.