By Dr. Sadik Omairey, Founder of NmeX Non-metallic Engineers Exchange

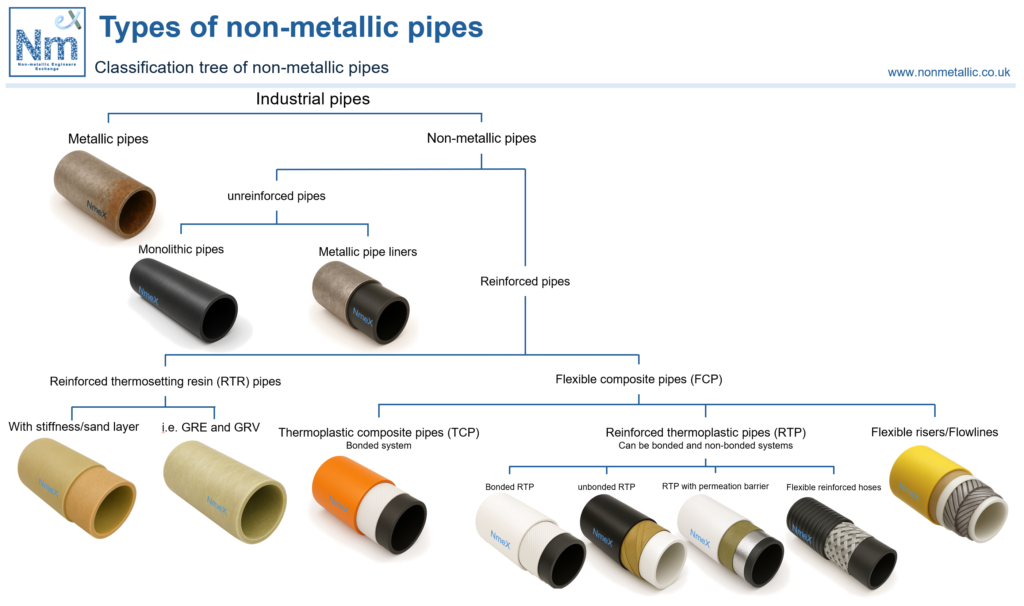

Non-metallic piping systems have become integral to modern engineering across sectors such as oil and gas, water infrastructure, chemical processing, and industrial manufacturing. Their advantages include corrosion resistance, lower weight, and easier installation compared to traditional metallic systems. However, understanding the diversity within non-metallic pipes is key to effective material selection.

This article explores the key categories of non-metallic pipes, examining their structure, typical applications, performance benefits, and design limitations. It aims to provide a practical reference point for engineers, specifiers, and asset owners involved in piping system design or material selection.

To provide better clarity, the figure below illustrates how these pipe types are organised into families based on structure. This visual comparison helps to distinguish between composite and non-composite types, bonded versus non-bonded reinforcements, and flexible versus rigid systems. It aims to provide a practical reference point for engineers, specifiers, and asset owners involved in piping system design or material selection.

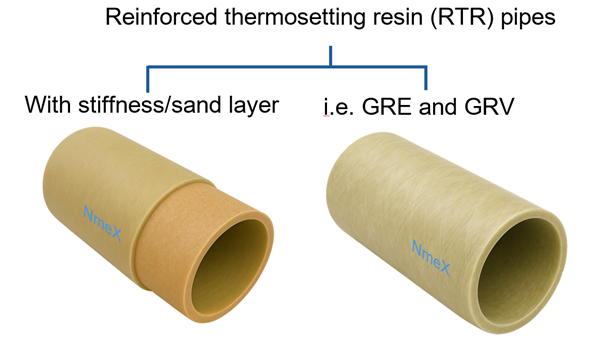

Reinforced Thermosetting Resin (RTR) Pipes, Also known as: Glass Reinforced Plastic (GRP)

RTR pipes are manufactured using continuous glass fibres embedded in thermosetting resins such as epoxy, vinylester, or polyester. Typically fabricated using filament winding, these pipes offer directional strength and tailored mechanical performance.

Structure: Filament-wound composite made of resin and continuous fibre reinforcement. Larger diameter pipes can have a stiffness (or sand) layer between the structural layers.

Applications: Water and wastewater treatment, chemical plants, desalination, firefighting systems, and offshore water injection lines.

Benefits:

- Excellent corrosion resistance

- High UV and chemical resistance

- Lightweight and easy to transport

- Suitable for large-diameter configurations

- Long service life

- Wide range of jointing options

Design Considerations:

- Brittle failure under impact or misalignment

- Joint performance depends on installer expertise

- Support and anchoring must be well designed

- Susceptible to localised damage if improperly handled

Thermoplastic Composite Pipes (TCP)

TCP represents a more advanced form of non-metallic pipe. It consists of a fully bonded multi-layer structure, typically with a thermoplastic liner, unidirectional fibre reinforcement (glass, aramid, or carbon), and an outer thermoplastic jacket.

Structure: Bonded laminate of thermoplastic and continuous fibre reinforcement

Applications: Offshore flowlines, high-pressure gas injection, subsea risers, and deepwater installations

Benefits:

- Fully bonded structure enhances integrity

- High fatigue and collapse resistance

- Spoolable in long lengths for easy deployment

- Excellent corrosion and chemical resistance

- High flow efficiency due to smooth bore

Design Considerations:

- Limited bending radius affects installation options

- Higher material and manufacturing costs

- Thermal performance depends on thermoplastic type

- Limited range of available diameters

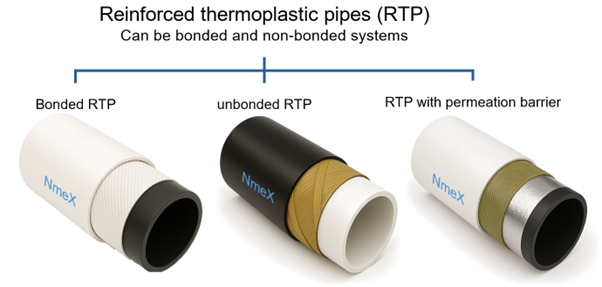

Reinforced Thermoplastic Pipes (RTP)

RTPs are a hybrid pipe consisting of a thermoplastic liner, a bonded or unbonded fibre reinforcement layer (fibers such as aramid, glass, or steel wires), and an outer protective jacket. Unlike TCP, not all layers have to be bonded. Additionally, some products have additional permeation barrier layers (thermoplastic or aluminum).

Structure: Three-layer structure (with additional permeation barrier in some cases) with flexible, bonded or non-bonded reinforcement.

Applications: Onshore oil & gas flowlines, water injection lines, multi phase chemical transport

Benefits:

- Lightweight and spoolable for fast installation

- Corrosion-free with long design life

- Good hydraulic performance

- Cost-effective compared to bonded composites

Design Considerations:

- Lower pressure capacity than TCP

- Risk of liner collapse under vacuum/rapid gas decompression (RGD)

- Limited resistance to high temperatures (depends on thermoplastic type)

- Requires careful handling to prevent damage.

Monolithic Thermoplastic Pipes

These pipes are made from a single thermoplastic material such as HDPE or PE-RT. They have a homogeneous wall and are typically joined by butt fusion.

Structure: Solid-wall thermoplastic pipe with no reinforcement

Applications: Water supply, gas distribution, wastewater systems, pipeline lining and rehabilitation

Benefits:

- High chemical resistance

- Flexible and shock-resistant

- Cost-effective in low- to medium-pressure applications

- Easy to fuse on-site with reliable joints

- Minimal maintenance over the lifetime

Design Considerations:

- Lower strength and stiffness compared to reinforced options

- Susceptible to UV degradation without protection

- Limited performance under high temperature or pressure

Lined Metallic Pipes

These combine a metallic outer pipe (usually carbon steel) with an internal thermoplastic liner (e.g., HDPE). The liner may be mechanically inserted or thermally bonded to form a corrosion-resistant barrier inside a structurally strong shell.

Structure: Steel pipe with corrosion-resistant plastic liner

Applications: Refineries, chemical plants, pipelines in corrosive environments, sour gas service

Benefits:

- High structural integrity from steel

- Excellent internal corrosion protection

- Cost-effective upgrade for existing metallic systems

- Reduced scale and internal fouling

Design Considerations:

- More complex jointing than monolithic pipes

- Liner may collapse under vacuum if not supported

- Liner expansion must be managed at temperature extremes

- Cannot be bent; requires straight-line routing or flanged elbows

- Reduce final pipe diameter

Flexible Reinforced Hoses

These are multi-layer short-length pipes with a thermoplastic liner, reinforcing braid (steel or synthetic), and an outer jacket. Designed for flexibility and vibration resistance.

Structure: Flexible hose with braided reinforcement and thermoplastic layers

Applications: Fuel lines, hydraulic hoses, and short flexible couplings in industrial systems

Benefits:

- Extremely flexible and easy to handle

- Absorbs vibrations and movement

- Resistant to abrasion and chemicals

Design Considerations:

- Short lengths only (not suitable for pipelines)

- Limited to moderate pressures and temperatures

- Degradation over time may require replacement

- Requires proper end fittings and clamping

Conclusion

Non-metallic pipes are not a single solution — they are a family of systems, each engineered for specific roles. Understanding their structures, strengths, and constraints allows engineers to make informed decisions, reduce lifecycle costs, and enhance reliability.

The goal of this classification is to provide clarity and technical grounding to support better material selection in the field.

About NmeX

The NmeX Non-metallic Engineers Exchange is a UK-based initiative focused on fostering knowledge sharing and collaboration in the field of non-metallic materials and structures. Through visual tools, technical insights, and community engagement, NmeX supports engineers, researchers, and industry professionals working at the frontier of composite and polymer engineering.